Home>Product>Sunflower oil pressing machine>Multifunctional fully automatic commercial use sunflower oil expeller

Home>Product>Sunflower oil pressing machine>Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

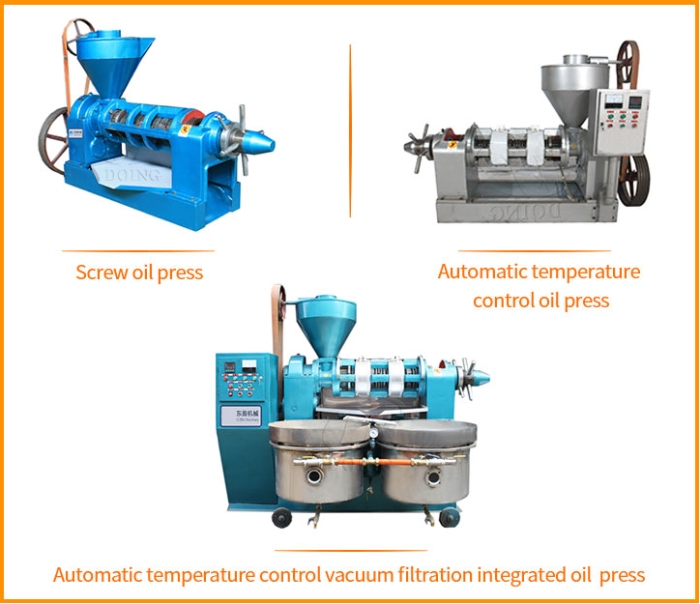

Multifunctional fully automatic commercial use sunflower oil expeller because of low investment cost, simple operation, factory direct sales and other characteristics are widely welcomed by customers. Henan Glory Company produce and manufacture three different types of sunflower oil expeller, respectively screw expeller, automatic temperature control oil expeller, automatic temperature control integrated oil expeller, they can not only be used for families or small workshops, but also can be used with other equipment for small, medium and large-sized sunflower oil production lines.

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

Screw oil expeller

The screw sunflower oil expeller produced by Doing Company is suitable for small edible oil processing plant or small oil mill. This series of single screw oil press machine can be widely used for pressing soybean oil, peanut oil, rapeseed oil, sunflower oil, cottonseed oil and so on.

♦Screw oil expeller parameters

| Equipment photo | Capacity (ton/day) | Residual oil in dry cake(%) | Weight(kg) |

|

1-20 | ≤7 | 195-1820 |

♦Screw oil expeller advantages

1.Stable performance: Composed of high-quality carbon steel which is robust and strong enough to bear wearings and tearings, suitable to ceaselessly oil pressing.

2.Widely used for pressing various oil seeds: such as peanut, soybean, sesame, flax seed, cottonseed, sunflower, etc; welcomed by medium and large size sunflower oil mills and plants.

3.With the proper-designed pressing chamber: the pre-heating process and rotation of the machine quickly increase the temperature in the chamber, which speeds up oil seeds inner structure breaking and pressed easily.

4.Save labor and energy: 60% electric power and 40% labor can be saved based on the same oil output.

♦Screw oil expeller working principle

When the screw sunflower oil expeller is in operation, the processed oil seeds will automatically enter the press chamber from the hopper, and the pressing screw will rotate to make the oil seeds continuously be pushed inward for pressing.

In the whole process, the oil seeds is in a moving state in press chamber of the single screw sunflower oil expeller. The pressure in the press chamber is very high. So there will be a large frictional resistance between the oil seeds and the pressing screw and the press chamber, which will cause friction between the particles of the oil seeds and cause relative movement.

Automatic temperature control oil expeller

Automatic temperature controlled oil expeller

Automatic temperature controlled oil expeller

Automatic temperature controlled oil expeller is a kind of oil press equipment with the automatic temperature control function, which is widely used in different edible oil processing plants. Automatic temperature controlled oil expeller uses an electric heating coil device to heat the press, and make the oil expeller pre-heated quickly and start the production quickly.

♦Automatic temperature control oil expeller parameter

| Equipment photo | Capacity (ton/day) | Residual oil in dry cake(%) | Weight(kg) |

|

1-11 | ≤7 | 300-830 |

♦Automatic temperature control oil expeller advantages

1. High oil yield: this automatic screw oil press adopts directional compression, multistage propulsion, and once-squeezing, the oil yield can increase 10% -30%.

2. Large production quantity: the working efficiency can be improved more than 30% by strengthening the feed system and increasing the propulsion speed.

3. Automatic control: this oil press can control the squeezing temperature automatically; built-in vacuum shunt can make the efficient separation of oil and residue.

4. Safe and convenient: simple structure covering small space; adopt totally enclosed protection to ensure safe and convenient operation.

5. Reliable and durable: adopt quality steel and fatigue-resisting castings to ensure reliable perfo rm a nee, which can realize long time and continuous running; the surface of automatic screw oil press adopts electrostatic spraying, which can resist over-high temperaturez clean and delicate.

♦Automatic temperature control oil expeller working principle

The working principle and operating process of automatic temperature controlled oil expeller are similar to those of traditional single screw oil expeller. They use mechanical force to squeeze the oil out from the oil seeds, so that the natural flavor and nutritional content of the edible oil are retained.

During operation process, firstly turn on the automatic temperature controlled system to heat the sunflower oil expeller to the specified temperature. Then the oil seeds will be transferred from the hopper into the press chamber. Under the squeeze screw rotation, the oil seeds are continuously pushed inward for squeezing oil out. And at last, the pressed oil will flow out from the outlet. By the way, if you want to get more pressed oil or low down the oil residual, multiple press operations can be performed.

Automatic temperature control integrated oil expeller

Automatic temperature controlled integrated oil expeller

Automatic temperature controlled integrated oil expeller

Automatic temperature controlled integrated oil expeller with vacuum filter is a kind of oil expeller very popular in the market at present, because it adds the vacuum filter based on the design of automatic temperature controlled oil expeller. Customers don't have to buy plate filter any more, and the vacuum filter can remove the impurities in the crude oil.

♦Automatic temperature control integrated oil expeller parameters

| Equipment photo | Capacity (ton/day) | Residual oil in dry cake(%) | Weight(kg) |

|

1-11 | ≤7 | 300-830 |

♦Automatic temperature control integrated oil expeller advantages

1. It is easy for people to learn, understand, and operate because of its small size. Besides, it is no special requirements for people to operate.

2. It costs less various expenses with lower electricity consumption in use.

3. The machine is comprehensive machine with filter machine, high oil yielding rate and pure oil quality.

4. The machine adopts automatic control system, automatic preheating control and automatic pressure control.

♦Automatic temperature control integrated oil expeller working principle

The working principle and working process of automatic temperature control oil pressing machine is similar to that of automatic temperature control oil pressing machine, which relies on mechanical force to extrude oil from oilseeds. The difference is that automatic temperature control oil pressing machine with filter device can filter the oil pressed out.

In the process of operation, first turn on the automatic temperature control system and heat the hydraulic press to the specified temperature. The oilseeds are then transferred from the hopper to the pressure chamber. The oil is pushed inward by the rotation of the extrusion screw, forcing the oil out. Finally, the pressed oil goes through the filter, and we get cleaner oil.

Henan Glory company has decades of experience in producing sunflower oil expeller, at the same time, we have a mature and experienced engineer team. So far, we have exported and installed cooking oil processing equipment in more than 90 countries, and received good feedback on the operation of cooking oil processing equipment.

Cooking oil processing equipment project photo

Cooking oil processing equipment project photo

Henan Glory company can not only customize sunflower oil production plan for you according to your actual needs, but also provide you with the latest quotation of sunflower oil expeller. If you are wondering how to choose the right sunflower oil expeller to carry out your sunflower oil business, welcome to consult at any time.

Leave a message

If you wanna to get more details about Multifunctional fully automatic commercial use sunflower oil expeller, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

How to ensure the normal operation of the sunflower oil making machine?

How to ensure the normal operation of the sunflower oil making machine?

-

How to buy sunflower oil processing machines in Kenya?

How to buy sunflower oil processing machines in Kenya?

-

The ultimate guide to the sunflower oil refining process

The ultimate guide to the sunflower oil refining process

-

How to save the cost of sunflower oil manufacturing machines?

How to save the cost of sunflower oil manufacturing machines?

-

Entire sunflower oil production line solutions

Entire sunflower oil production line solutions

-

What equipment is needed to set up a full sunflower oil refining plant?

What equipment is needed to set up a full sunflower oil refining plant?