Entire sunflower oil production line solutions

When you’re planning to launch a sunflower oil production project, do you often get stuck with these worries? If you source pretreatment, extraction, and refining equipment from different suppliers, will mismatched components cause production bottlenecks? Will inconsistent standards across processes compromise the oil’s quality and food safety? Or will fragmented technical support leave you stranded when the line hits issues after startup?

Henan Glory provides you with an entire turnkey sunflower oil production line to address your concerns.

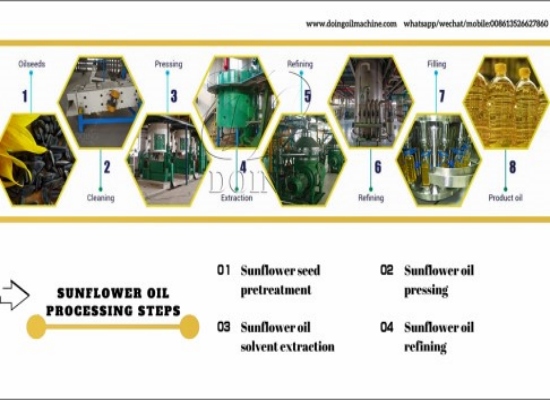

Entire sunflower oil production line

Entire sunflower oil production line

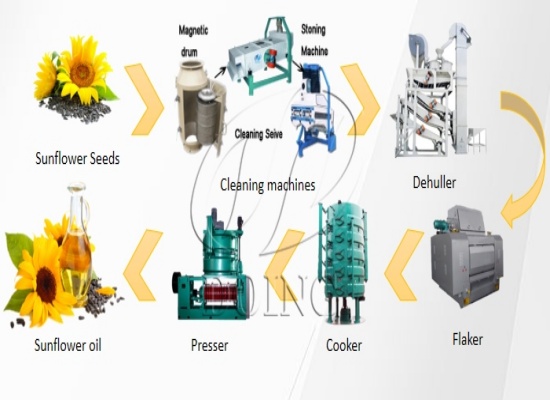

1. Seeds Preparation and Pretreatment

This initial stage is crucial for ensuring high oil yield and quality, and it also helps protect downstream equipment.

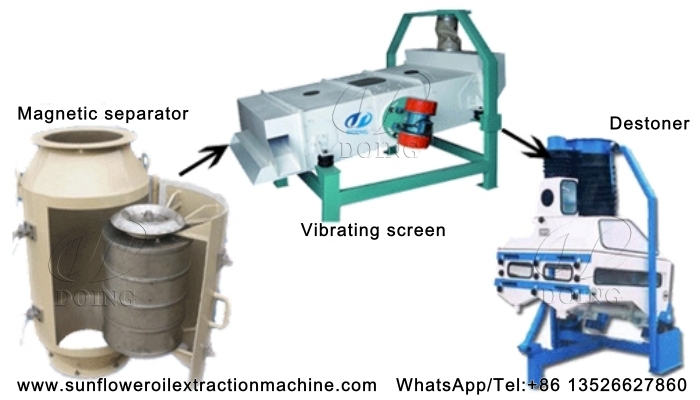

Cleaning: Raw sunflower seeds contain impurities such as stems, leaves, sand, stones, and metal fragments. Cleaning equipment (including vibrating screen, magnetic separator, and destoner) removes these impurities to prevent equipment damage and ensure the purity of sunflower oil.

Sunflower seeds cleaning equipment

Sunflower seeds cleaning equipment

Dehulling (Cracking and Separation): Sunflower seed shells are high in fiber and wax but low in oil content. Dehulling is necessary to remove them. Seeds are first cracked using cracker. Kernel husk separator then efficiently separate the kernels from the shells. This step increases the protein content of the subsequent meal by-product.

Flaking and Conditioning: The sunflower seed kernels are rolled into thin flakes by flaking machines. These flakes are then conveyed to multi-layered cooker for conditioning. Conditioning is critical as it adjusts moisture content and temperature, coagulates proteins, and breaks down oil cells, significantly optimizing the efficiency of the subsequent oil extraction step.

2. Oil Extraction

This is the core process of separating oil from the sunflower seed flakes. Two primary methods are used, often in combination.

Mechanical Pressing: The conditioned flakes are fed into a screw oil expeller. Inside the press chamber, a rotating screw shaft continuously advances the material, creating increasing pressure that squeezes out the oil. This is a physical process, which better preserves the oil's natural flavor and nutrients.

Solvent Extraction (Optional): The cake from the screw oil expeller retains some residual oil. TIn order to achieve the highest possible oil yield (over 99%), you can send this cake to a solvent extraction plant. Here, a food-grade solvent (typically hexane) dissolves the remaining oil. The solvent is then recovered from both the oil and the meal through distillation and is reused. The end products are crude sunflower oil and defatted meal.

Sunflower oil extraction equipment

Sunflower oil extraction equipment

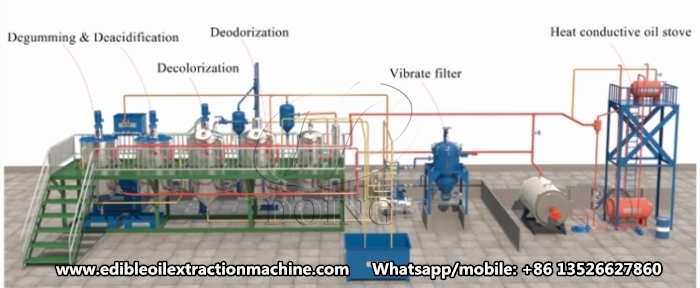

3. Sunflower Oil Refining

Crude sunflower oil contains gums, free fatty acids (FFA), pigments, odoriferous compounds, and waxes. Refining equipment removes these impurities to produce a clear, stable oil with a mild flavor and improved shelf life.

Degumming: This first step, often carried out using water or acid, removes hydratable and non-hydratable phosphatides (gums) to prevent the sunflower oil from becoming hazy.

Deacidification: An alkali solution (e.g., NaOH solution) is added to react with FFA, forming soapstock. This soapstock is then separated via centrifugation.

Bleaching: In a bleaching tank, adsorbents like activated white clay are mixed with the sunflower oil to remove pigments, residual soaps, and oxidation products, improving the oil's color.

Deodorization: This is a key step conducted under high temperature and vacuum. Steam is passed through the oil to strip away volatile odor and flavor compounds, resulting in a neutral-smelling and tasting oil.

Dewaxing: Specific to sunflower oil, this optional step removes waxes to prevent cloudiness at cooler temperatures. The oil is slowly cooled in crystallizer to allow wax crystals to form, which are then removed by filter.

Sunflower oil refining equipment

Sunflower oil refining equipment

4. Sunflower Oil Packaging and Storage

The final refined sunflower oil is stored in large tanks, often under a nitrogen blanket to prevent oxidation. The oil is then automatically pumped to filling machines to be packaged into bottles, plastic jugs, flexitanks, or drums. The packaging line typically includes capping, labeling, and case-packing machines, and is followed by palletizing for shipment.

If you are preparing to launch or expand your sunflower oil production project, contact us and let Henan Glory's turnkey solutions help you turn plans into results faster.

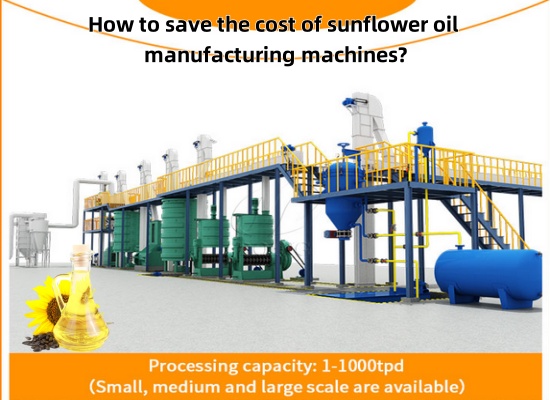

PREV:How to save the cost of sunflower oil manufacturing machines?

PREV:How to save the cost of sunflower oil manufacturing machines?

NEXT:What equipment is needed to set up a full sunflower oil refining plant?

NEXT:What equipment is needed to set up a full sunflower oil refining plant?

Leave a message

If you wanna to get more details about Entire sunflower oil production line solutions, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?