The ultimate guide to the sunflower oil refining process

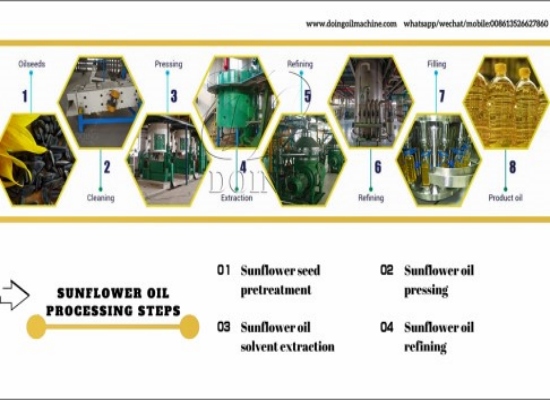

Sunflower oil is one of the world's most popular vegetable oils, beloved for its mild flavor, rich nutritional value , and versatility.But have you ever wondered how the crude oil pressed from sunflower seeds is transformed into the clear, golden liquid we love when cooking? This transformation requires a crucial process: sunflower oil refining. This process ensures the sunflower oil's safety and stability. In this ultimate guide, we'll break down the sunflower oil refining process step by step, revealing the meticulous steps it undergoes to become an indispensable culinary companion.

Sunflower oil

Sunflower oil

Sunflower oil begins as "crude oil," pressed directly from sunflower seeds. In this natural state, it contains impurities like gums, free fatty acids, pigments, and waxes. If bottled immediately, this unrefined sunflower oil would have a darker color, a stronger flavor, and a much shorter shelf life. More importantly, these natural impurities can affect both your health and your cooking results. That’s why sunflower oil refining is essential—it carefully removes these unwanted elements while preserving the sunflower oil’s quality and nutritional value.

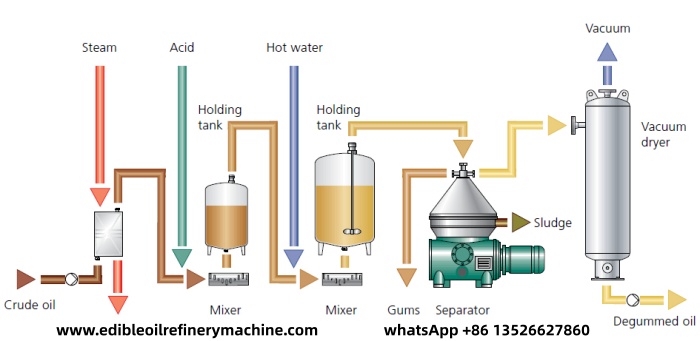

The first sunflower oil refining step focuses on clarity. Crude sunflower oil contains colloidal impurities, mainly phospholipids, which can cause the oil to be turbid and affect its storage stability and subsequent sunflower oil refining processes. Hydration degumming and phosphoric acid degumming are two common sunflower oil refining methods. In the former, hot water or an electrolyte solution is added to heated crude sunflower oil while stirring. The colloidal impurities absorb water, coagulate, and precipitate, and are subsequently separated from the oil via sedimentation or centrifugation. During this process, the hydration temperature is usually set at 50-80 °C, and the hydration time is 15-30 minutes. For the latter, when adding 85% phosphoric acid, the amount of phosphoric acid used is about 0.05% - 0.2% of the oil weight, which can be adjusted according to the actual phosphorus content of sunflower oil.

Sunflower oil degumming process

Sunflower oil degumming process

Next, it’s time to address acidity. Free fatty acids present in the crude sunflower oil can give it a sharp or unpleasant taste and cause it to spoil faster. Alkali refining is the main method for sunflower oil deacidification. The process involves adding sodium hydroxide solution to sunflower oil, which then reacts with the free fatty acids to form soapstock. The soapstock is then separated from the oil by centrifugation. This step is key to achieving the oil’s signature mild flavor and extending its shelf life. In addition to alkali refining, distillation deacidification (physical refining) can also be used, which removes free fatty acids by distillation under high vacuum conditions.

Sunflower oil deacidification equipment

Sunflower oil deacidification equipment

Natural pigments from the sunflower seeds give the unrefined sunflower oil a dark color. To create the light, appealing appearance you expect, these pigments, along with any remaining impurities and trace metals, need to be removed. Typically, sunflower oil is treated with natural adsorbents such as activated clay, fuller's earth, or activated carbon. After filtration to remove the spent adsorbents, the oil is left with the pure, golden color characteristic of high-quality sunflower oil.

Sunflower oil decolorization equipment

Sunflower oil decolorization equipment

At this stage, the sunflower oil is nearly pure but may still carry subtle odors or flavors from the seed. Deodorization removes volatile odorous substances, such as aldehydes and ketones, thereby neutralizing unwanted flavors and odors to produce a neutral-tasting oil. Generally, under high temperature (220-260℃) and high vacuum conditions, hot dry steam is passed through the oil in a deodorization pot or tower. This process gently carries away all the volatile odor compounds, leaving behind a clean-tasting oil without altering its healthy fat composition.

Sunflower oil deodorization equipment

Sunflower oil deodorization equipment

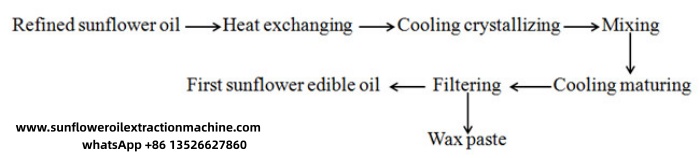

Some sunflower oils naturally contain small amounts of wax, which can make the oil appear cloudy, especially when stored in a cool place. The common dewaxing method is the cooling-crystallization method. The deodorized sunflower oil is cooled in a crystallization tank to make the waxes precipitate out in the form of crystals. These crystals are then filtered out, guaranteeing that your sunflower oil remains perfectly clear and bright, even on a cold day.

Sunflower oil dewaxing process

Sunflower oil dewaxing process

Before bottling, the refined sunflower oil undergoes rigorous quality control. Parameters such as acidity, color, and purity are all tested against strict food safety standards. Only after passing these tests is the oil packaged in light-protected bottles or tins to preserve its freshness, flavor, and nutritional benefits.

In summary, the sunflower oil refining process transforms crude sunflower oil into the safe, high-quality, and versatile cooking oil found on store shelves. Consistently achieving this requires not only meticulous process control but also robust and efficient technology. For producers seeking to maximize their quality and profitability, Henan Glory Company provides the industry-leading solutions. We supply advanced sunflower oil refining equipment and comprehensive technical support, engineered to deliver exceptional results and a rapid return on investment.

PREV:How to buy sunflower oil processing machines in Kenya?

PREV:How to buy sunflower oil processing machines in Kenya?

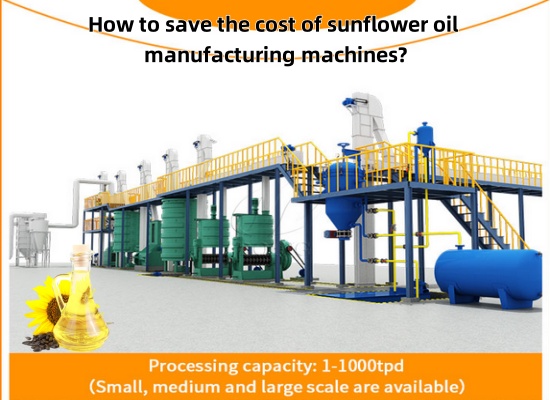

NEXT:How to save the cost of sunflower oil manufacturing machines?

NEXT:How to save the cost of sunflower oil manufacturing machines?

Leave a message

If you wanna to get more details about The ultimate guide to the sunflower oil refining process, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?