Home>Product>Sunflower oil solvent extraction plant>Solvent extractor for sunflower oil extraction plant

Home>Product>Sunflower oil solvent extraction plant>Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

Introduction of solvent extractor:

Solvent extractor is used in sunflower oil making industry, using n-hexan to extract oil from sunflower seeds. There are three main types of extractor currently employed commercially in the sunflower oil making industry: Rotocel extractor, Loop type extractor and Ballyuan extractor. The first two kinds are common used, so I will introduce them in the following text.

Rotocel extractor in sunflower oil extraction plant:

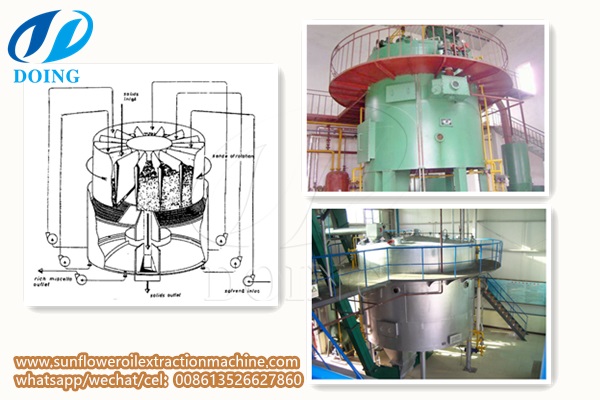

Rotocel extractor for sunflower oil extraction plant

Rotocel extractor for sunflower oil extraction plant

Features of Rotocel extractor in sunflower oil extraction plant:

1. As the picture shows, rotocel extractor is horizontal in structure. The major parts of extractor have adopted stainless steel to fix grid plate and increase the horizontal grid plates, which can prevent the miscella from flowing back to the blanking case in order to guarantee good extraction effect.

2. Compact structure, high material layer, reliable operation and low power consumption; The rotocel extractor is with low rotating speed, low power, easy operation, without noise and low maintenance cost.

The technology requirements of rotocel extractor for sunflower oil extraction plant:

1. The material temperature dip 50-58 ℃, leaching temperature above 50 ℃;

2. The solvent temperature 50-55 ℃;

3. Extractor operating cycle 75-120min;

4. Soluble material ratio of 1: (0.7-1.3);

5. The amount of solvent wet meal containing 15% -40%.

Loop type extractor in sunflower oil extraction plant:

Loop type extractor for sunflower oil extraction plant

Loop type extractor for sunflower oil extraction plant

Continuous loop type extractor is economical and efficient, and very suitable for large sunflower oil extraction plant. Utilizing loop type extractor is for the following reasons.

The running process character of loop extractor:

The continuous loop extractor conveys material through the extractor using a drag conveyor. The material is immersed in solvent and passes through sections of concurrent and counter current flow. As the material moves through the extractor it is rotated completely so that the lower side of the material becomes the upper side, this gives the solvent easy access to the material from all directions and ensures a high level of oil extraction.

Operational Features of loop extractor:

There are six main factors governing an extractors efficiency. These are, the retention time –or ‘contact time’-, extractor temperature, number of miscella stages, miscella flux rate, particle thickness and solvent retention value.

Solvent extraction is favoured when the oil content of the material is below 30% of the total weight. The total oil content of sunflower seeds is higher than 30% by weight, so the pre-press solvent extraction method is used. If the total oil content is below 30%, the direct solvent extraction method is used. The main difference between the two processes is that prepress process extracts oil mechanically prior to solvent extraction.

This is the introduction of solvent extractor used in sunflower oil solvent extraction plant. Using solvent extraction method, it's possible to reduce the oil content to approximately 1% of the total weight. This makes solvent extraction a very economical means of extraction compared to traditional mechanical extraction.

Leave a message

If you wanna to get more details about Solvent extractor for sunflower oil extraction plant, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

How to ensure the normal operation of the sunflower oil making machine?

How to ensure the normal operation of the sunflower oil making machine?

-

How to buy sunflower oil processing machines in Kenya?

How to buy sunflower oil processing machines in Kenya?

-

The ultimate guide to the sunflower oil refining process

The ultimate guide to the sunflower oil refining process

-

How to save the cost of sunflower oil manufacturing machines?

How to save the cost of sunflower oil manufacturing machines?

-

Entire sunflower oil production line solutions

Entire sunflower oil production line solutions

-

What equipment is needed to set up a full sunflower oil refining plant?

What equipment is needed to set up a full sunflower oil refining plant?