What machines are needed to set up a large sunflower oil mill plant?

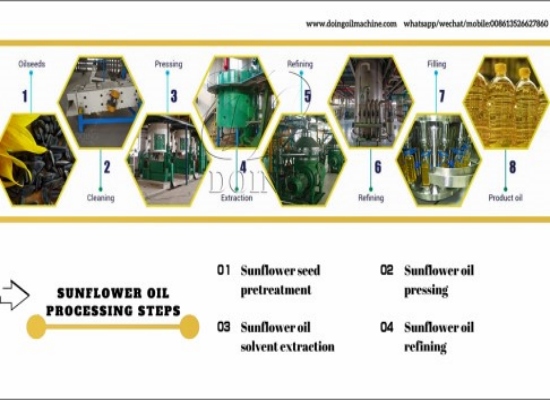

Setting up a large sunflower oil mill plant is a complex process that requires careful planning, significant investment and the right sunflower oil mill machines to ensure efficient production. The goal is to transform sunflower seeds into high-quality sunflower oil, which involves multiple sunflower oil mill machines. This article uses the solution provided by Henan Glory Company as an example to outline the basic machines are needed to set up an efficient and robust large sunflower oil mill plant.

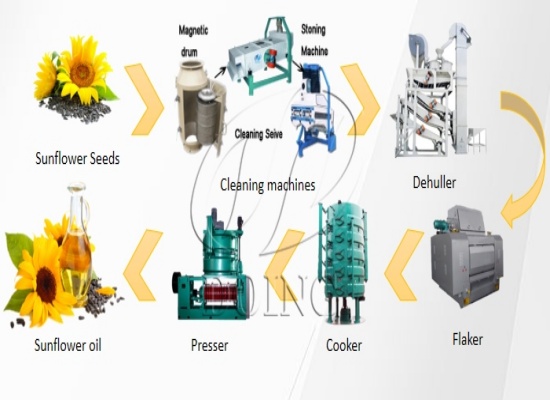

1. Sunflower Seed Pretreatment Machines

In order to ensure the best oil yield and quality, it is necessary to start with the pretreatment of sunflower seeds:

(1) Sunflower seed cleaning machines: equipped with a vibrating screen, destoner and magnetic separator, it can remove dust, stones, heavy foreign matter and metal impurities. At the same time, it can protect downstream sunflower oil mill machines from damage.

Sunflower seed cleaning machines

Sunflower seed cleaning machines

(2) Sunflower seed dehulling machine: separates the sunflower seed shell from the kernel, improves sunflower oil extraction efficiency and reduces processing costs.

Sunflower seed dehulling machine

Sunflower seed dehulling machine

(3) Sunflower seed kernel and shell separation sieve: according to the shape, size and specific gravity difference of the sunflower seed shell and kernel, the sunflower seed shell and kernel are separated by screening method.

(4) Sunflower seed cooking machine: used to bake sunflower seeds to the appropriate humidity and temperature.

Sunflower seed cooking machine

Sunflower seed cooking machine

2. Sunflower Oil Extraction Machines

Choosing advanced sunflower oil extraction machines can help achieve the highest productivity:

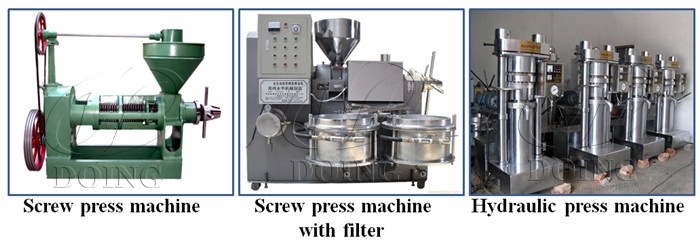

(1) Sunflower oil pressing machines: Henan Glory Company can provide sunflower oil pressing machines of various types, such as hydraulic sunflower oil pressing machine, screw sunflower oil pressing machine and automatic temperature control integrated sunflower oil pressing machine, which mechanically press sunflower seeds to extract sunflower oil. For large sunflower oil mill plant operations, continuous screw sunflower oil pressing machines are usually used, which can produce stable sunflower oil production while minimizing residual sunflower oil in the cake.

Sunflower oil pressing machines

Sunflower oil pressing machines

(2) Sunflower oil solvent extraction machine: It is very suitable for large sunflower oil mill plant industrial applications. Through advanced chemical solvent (usually n-hexane) extraction technology, the oil recovery rate is as high as 99%. The sunflower oil solvent extraction machine manufactured by Henan Glory Company specifically includes solvent extraction system, D.T.D.C. system, evaporation stripping system and condenser & recovery system. This sunflower oil solvent extraction machine can minimize the residual oil in the sunflower oil cake and significantly increase the yield of sunflower oil.

Sunflower oil solvent extraction machine

Sunflower oil solvent extraction machine

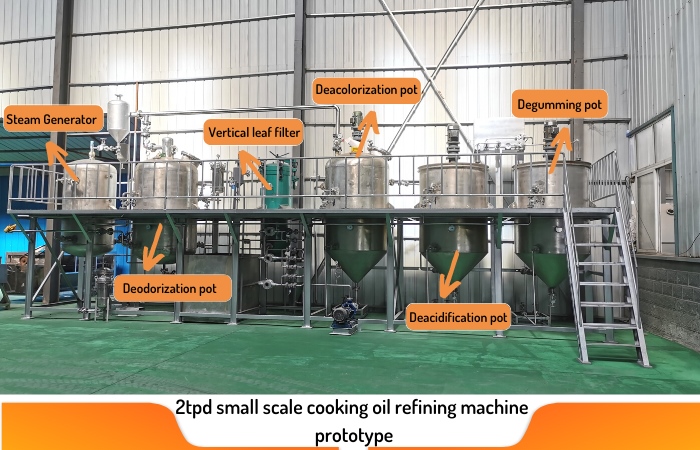

3. Sunflower Oil Refining Machines

Using an integrated sunflower oil refining production line, crude sunflower oil can be refined into high-quality edible sunflower oil:

(1) Sunflower oil degumming machine: used to remove phospholipids from crude sunflower oil.

(2) Sunflower oil deacidification machine: by using alkali solution (usually sodium hydroxide solution) to neutralize free fatty acids and thus inhibit the increase of free fatty acids.

(3) Sunflower oil decolorization machine: by using bleaching earth (usually activated white clay) to remove pigments, soap bases, trace metals and other impurities.

(4) Sunflower oil deodorization machine: used under high vacuum and low pressure conditions to remove volatile compounds that cause oil to have odor or odor, so that the sunflower oil remains neutral and odorless.

Sunflower oil refining machines

Sunflower oil refining machines

(5) Sunflower oil dewaxing machine: using the characteristics of sunflower oil and wax with a large difference in melting point, through cooling, crystallization, and then filtering or centrifugal separation to separate oil and wax, thereby improving the transparency and stability of sunflower oil.

4. Sunflower Oil Filtration and Packaging Machines

The following sunflower oil mill machines can be used to ensure product purity and market competitiveness:

(1) Sunflower oil filtering machine: Plate and frame filter is usually used, which can remove fine impurities to make the sunflower oil transparent and durable.

Sunflower oil filtering machine

Sunflower oil filtering machine

(2) Automated sunflower oil bottling production line: simplifies the filling, capping, labeling and packaging processes to ensure efficiency and hygiene.

Sunflower oil bottling production line

Sunflower oil bottling production line

To summarize, setting up a large sunflower oil mill plant needs a significant investment in specialized sunflower oil mill machines tailored for each stage of production. From seed cleaning to packaging the sunflower oil for sale, each step requires specialized sunflower oil mill machines to ensure efficiency and product quality. In addition, implementing quality control measures is also essential to producing sunflower oil that meets industry standards and consumer expectations. If you want to choose the sunflower oil mill machines and processes that will allow your sunflower oil mill plant to run smoothly and produce high-quality sunflower oil, please feel free to contact Henan Glory Company. Not only can we customize the equipment configuration according to your production capacity and budget, but we can also provide you with end-to-end services, from plant design to installation and training, we will support you all the way!

PREV:What are the advantages of sunflower oil refinery process?

PREV:What are the advantages of sunflower oil refinery process?

NEXT:How to increase sunflower oil yield during sunflower oil production?

NEXT:How to increase sunflower oil yield during sunflower oil production?

Leave a message

If you wanna to get more details about What machines are needed to set up a large sunflower oil mill plant?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

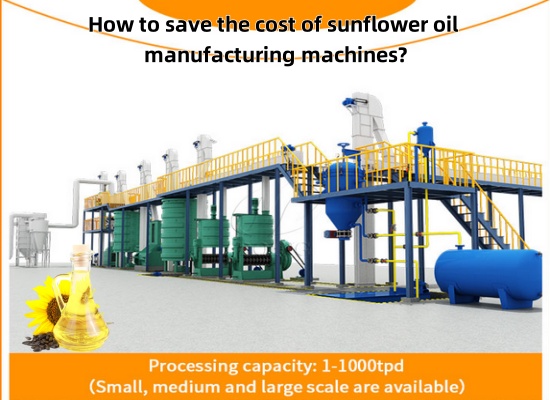

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?