How to increase sunflower oil yield during sunflower oil production?

In the field of edible oil processing, sunflower oil is highly favored by consumers for its rich nutritional content and distinct flavor. This article will unveil key measures to increase sunflower oil yield during sunflower oil production process, aiding your sunflower oil mill in achieving efficient production.

1. Optimize Raw Material Selection and Pretreatment

(1) Select Premium Raw Materials: Choosing sunflower seeds that are plump, free from pests and diseases and low in impurities is the foundational step to increase sunflower oil yield. High-quality sunflower seeds inherently possess higher oil content, setting a solid stage for subsequent sunflower oil processing.

Premium sunflower seeds

Premium sunflower seeds

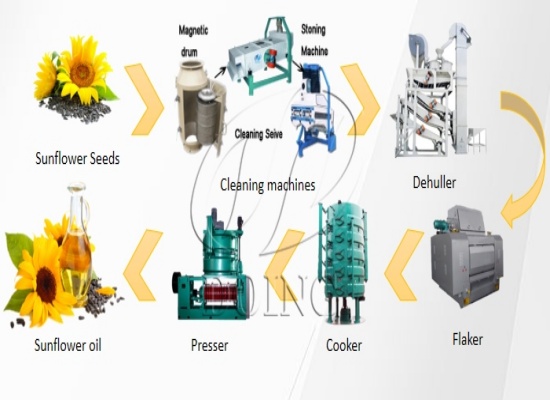

(2) Clean the Sunflower Seeds Thoroughly: Employ advanced sunflower seed cleaning equipment, such as vibrating screens, destoners and magnetic separators, to meticulously eliminate impurities from sunflower seeds. These include dust, broken shells, stones and metallic debris. Such impurities not only compromise sunflower oil quality but also accelerate sunflower oil production equipment wear during sunflower oil processing, thereby reducing sunflower oil yield.

Sunflower seed cleaning equipment

Sunflower seed cleaning equipment

(3) Remove the Shells from Sunflower Seeds Efficiently: Utilize advanced sunflower seeds shelling technologies, like friction or squeeze shelling, to remove sunflower seed shells. Shelling reduces impurity content in the sunflower oil, enhances oil purity, and minimizes sunflower oil production equipment wear, thus extending sunflower oil production equipment lifespan.

Sunflower seeds shelling equipment

Sunflower seeds shelling equipment

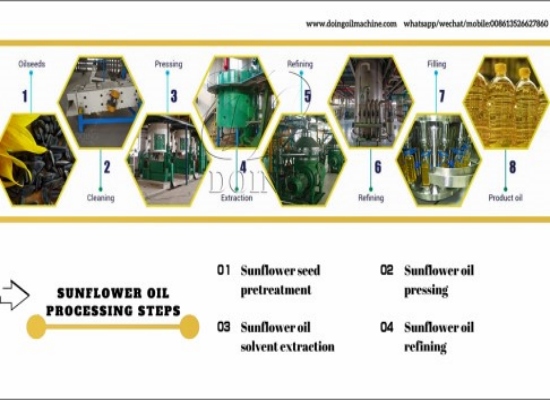

2. Employ Advanced Sunflower Oil Production Technology

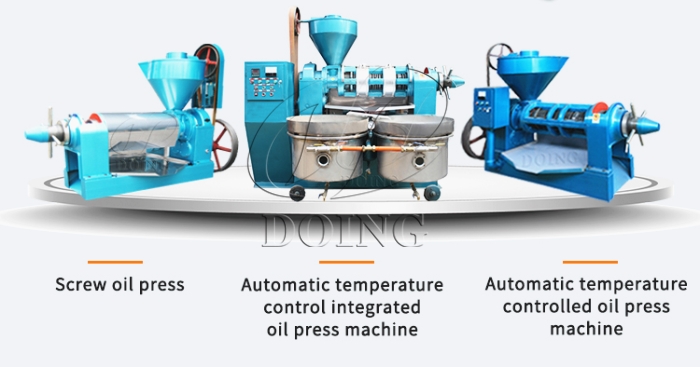

(1) Optimize Pressing Method: Pressing is a physical extraction method that preserves sunflower oil's natural nutrients. To optimize pressing efficiency, you can use advanced advanced screw or hydraulic sunflower oil press equipment, characterized by high output, low cake residue, and superior cake quality. Adjusting parameters such as pressing temperature, pressure, and duration can further increase sunflower oil yield.

Advanced screw sunflower oil press equipment

Advanced screw sunflower oil press equipment

(2) Implement Solvent Extraction Method: Solvent extraction method leverages the solubility of sunflower oil in solvents for more efficient extraction. Henan Glory Company(with branch and overseas warehouse in Nigeria) provides advanced sunflower oil solvent extraction equipment, including solvent extraction system, D.T.D.C system, evaporative stripping system and condenser & recovery system, to ensure seamless solvent extraction. This method can minimize residual oil in the sunflower oil cake, significantly increasing sunflower oil yield.

Advanced sunflower oil solvent extraction equipment

Advanced sunflower oil solvent extraction equipment

(3) Combine Pre-Pressing and Solvent Extraction: For large-scale sunflower oil mills, we recommend combining pre-pressing with solvent extraction. Initially, sunflower seeds are pre-pressed to obtain pre-pressed sunflower oil and cakes, which are then the sunflower oil cake is then subjected to solvent extraction to further recover the sunflower oil. This approach maximizes sunflower seed utilization, increases sunflower oil yield and reduces energy consumption.

3. Enhance Sunflower Oil Production Equipment Performance and Automation

(1) Choose High-Quality Sunflower Oil Production Equipment: In this regard, I recommend the sunflower oil production equipment of Henan Glory Company to you. Their sunflower oil production equipment is crafted from premium materials and undergoes rigorous quality checks to ensure stability and durability. High-quality sunflower oil production equipment reduces downtime, boosts sunflower oil production efficiency, and indirectly increases sunflower oil yield.

High-quality sunflower oil production equipment

High-quality sunflower oil production equipment

(2) Prioritize Energy-Saving Design of Sunflower Oil Production Equipment: Henan Glory's sunflower oil production equipment uses advanced energy-saving technologies and materials to reduce energy consumption during operation. This not only reduces sunflower oil production costs, but also improves sunflower oil production equipment efficiency and further increases sunflower oil yield.

4. Strengthen Sunflower Oil Production Management

Establish a Robust Quality Management System: Implement a comprehensive quality management system for your sunflower oil mill to rigorously monitor and manage each sunflower oil production stage. This will not only ensure the consistent quality of sunflower oil, but also improve production efficiency and management level.

In summary, it takes many measures to increase sunflower oil yield during sunflower oil production process. As a professional edible oil production equipment supplier, we are committed to providing customers with first-class sunflower oil production equipment and perfect services to help your sunflower oil mills achieve efficient production, increase output and create greater economic benefits. If you have any needs, please contact us immediately!

PREV:What machines are needed to set up a large sunflower oil mill plant?

PREV:What machines are needed to set up a large sunflower oil mill plant?

NEXT:What is the difference between the two extraction processes for sunflower oil?

NEXT:What is the difference between the two extraction processes for sunflower oil?

Leave a message

If you wanna to get more details about How to increase sunflower oil yield during sunflower oil production?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?