What is the difference between the two extraction processes for sunflower oil?

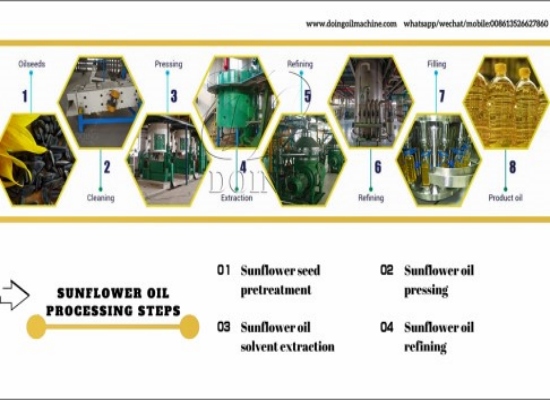

In the competitive edible oil industry, the choice of extraction method directly impacts product quality, market appeal and profitability. As a leading manufacturer of sunflower oil extraction equipment, we help producers make informed decisions by understanding the difference between the two extraction processes for sunflower oil. Learn how the right technology can unlock premium sunflower oil extraction and meet evolving consumer demands. There are some differences between pressing and solvent extraction of sunflower oil.

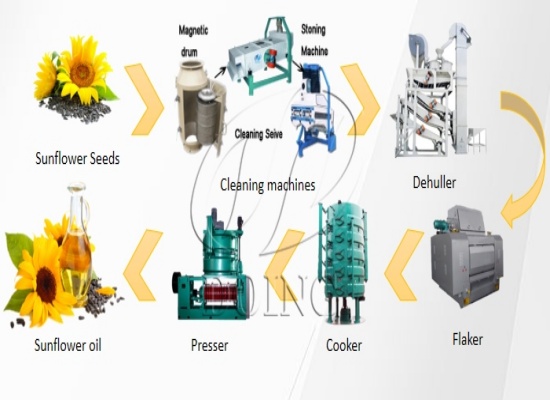

1. Different processing technology:

Pressing method is the first choice of most people. Pressing method also named mechanical pressing. According to the customer's choose, there are kinds of sunflower oil pressing equipment can be used. Pressing is using mechanical pressing to get sunflower oil out, while solvent extraction is using N-hexane to extract the crude oil out, which belongs to chemical method. Large-scale edible oil solvent extraction method is another method for extracting sunflower oil, which have some impact on the environment, so environmental protection issues need to be considered. Therefore, when using the edible oil solvent extraction method, it is necessary to choose environmentally friendly and safe chemical solvents, strictly control the amount used and emissions, and reduce the impact on the environment.

Two extraction processes for sunflower oil

Two extraction processes for sunflower oil

2. Residual Oil Rate:

Sunflower Oil Pressing: This method typically results in a higher residual oil rate, generally about 6%-7%.

Sunflower Oil Solvent extraction: This method can achieve less than 1% residual oil content, making it the preferred method for maximizing sunflower oil extraction efficiency.

Sunflower oil solvent extraction machines

Sunflower oil solvent extraction machines

3. Oil Quality:

Sunflower Oil Pressing: Produces a more natural sunflower oil with better flavor and fewer chemical residues. This method is often favored for premium products.

Sunflower Oil Solvent extraction: While it yields more sunflower oil, it may result in sunflower oil with trace solvents and lower sensory qualities. Additional refining steps are usually necessary.

Sunflower oil

Sunflower oil

4. Cost Considerations:

This is probably one of the most important difference between pressing and solvent extraction of sunflower oil for customers.

Sunflower Oil Pressing: Generally involves lower initial investment and operational costs, making it suitable for small to medium-scale operations.

Sunflower Oil Solvent extraction: Requires a higher initial investment in sunflower oil extraction equipment and ongoing solvent costs, making it more viable for large-scale operations where high volume is necessary. In this regard, the sunflower oil extraction machine engineer of Henan Glory Company recommends that you can choose the solvent extraction method for extracting sunflower oil when your production capacity is above 30tpd. In other words, if your production capacity is small, it is not cost-effective to buy sunflower oil extraction equipment.

In conclusion, understanding difference between the two extraction processes for sunflower oil is essential for making an informed decision in sunflower oil extraction. By considering factors such as oil yield, quality, cost and environmental impact, etc, clients can choose the right extraction method that aligns best with their sunflower oil extraction goals. If you have any questions about sunflower oil extraction, welcome to reach out to us for further information or inquiries about our sunflower oil extraction solutions. Let us help you optimize your sunflower oil extraction for quality and efficiency!

PREV:How to increase sunflower oil yield during sunflower oil production?

PREV:How to increase sunflower oil yield during sunflower oil production?

NEXT:Why stainless steel material is critical for sunflower oil refining equipment?

NEXT:Why stainless steel material is critical for sunflower oil refining equipment?

Leave a message

If you wanna to get more details about What is the difference between the two extraction processes for sunflower oil?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?