How to make sunflower oil in sunflower oil mill plant?

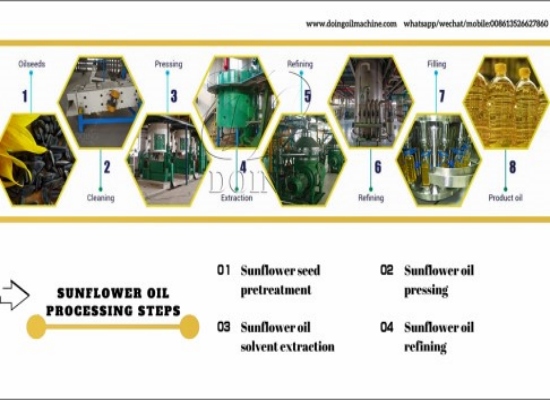

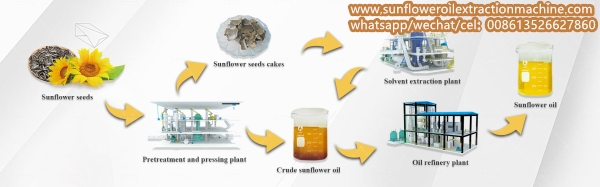

In more than 30 tons per day, large scale sunflower oil mill plant, four workshops are step by step to make sunflower oil. Let me explain for you. These four workshops are sunflower seeds pretreatment and pressing workshop, sunflower oil solvent extraction workshop, crude sunflower oil refinery and dewaxing workshop, and sunflower oil filling workshop. And then bottled or barreled sunflower oil can be sold in the supermarket.

Large scale sunflower oil mill plant can produce not only high quality sunflower oil, but also large amount of sunflower oil, because of the solvent extraction technology can extract oil from pressed cakes. What's more, such full-automatic sunflower oil production line will make the residual oil rate least. So, setting up a large scale sunflower oil mill plant is a good choice, if you have enough budget.

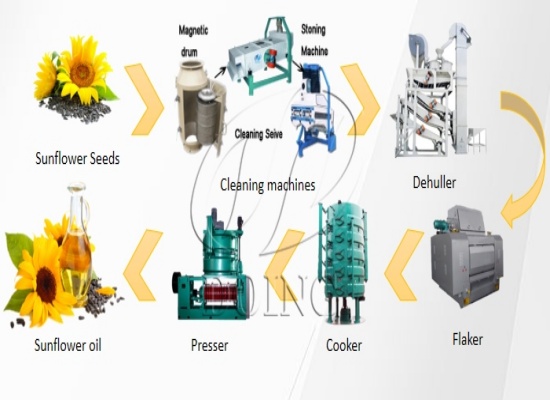

Sunflower oil making process flow chart in sunflower oil mill plant

Sunflower oil making process flow chart in sunflower oil mill plant

Every workshop in large scale sunflower oil mill plant has its own function and working process. Of course, only every part works well, the complete sunflower oil mill plant can make more profit.

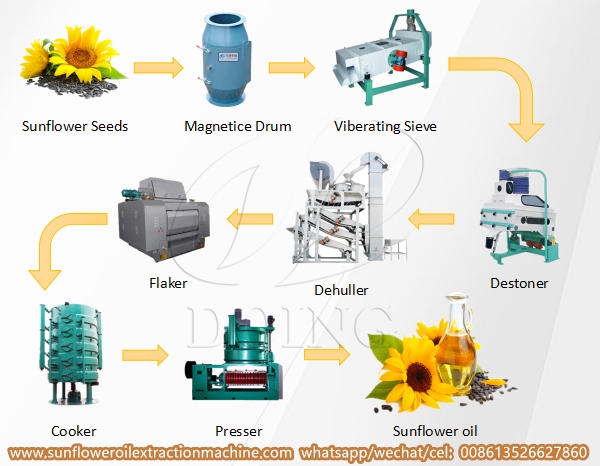

Firstly, the sunflower seeds pretreatment and pressing workshop has three functions. 1) Cleaning the sunflower seeds to make sure there is not impurities that can damage the machines; 2) Adjusting the size, inner structure, temperature and moisture of sunflower seeds to get better pressing effect; 3) Extract sunflower oil by sunflower oil press machine or pre-press machine.

Machines in sunflower seeds pretreatment and pressing workshop

Machines in sunflower seeds pretreatment and pressing workshop

Next, the sunflower oil solvent extraction workshop only has one main function. That is to extract oil from pressed cakes by solvent. However, as I referred in second paragraph, the residual oil rate of meal got from sunflower oil solvent extraction workshop can be less than 1%. That is also the reason why many customer want to use solvent extraction technology in their sunflower oil mill plant.

Machines in sunflower oil solvent extraction workshop

Machines in sunflower oil solvent extraction workshop

Thirdly, the crude sunflower oil refinery and dewaxing workshop is also important part in complete sunflower oil mill plant, which can make crude sunflower oil become standard sunflower product oil. It has five main steps, degumming, deacidification, decolorization, deodorization and dewaxing. The first four parts belong to the heating plant, and the last part is cooling plant, so they are separated.

Three types of sunflower oil refinery machine

Three types of sunflower oil refinery machine

At last, it is sunflower oil filling workshop. Its main function is to packing and filling the product sunflower oil. In large scale sunflower oil mill plant, usually use full-automatic sunflower oil filling line. Besides, some customers also bought blow modeling machine to make sunflower oil bottle by themselves.

Sunflower oil filling workshop

Sunflower oil filling workshop

All the workshops that I referred before are necessary for a large scale sunflower oil mill plant. Henan Doing Company has finished such projects before and has rich experience. You can also choose to set up a medium scale or small scale sunflower oil mill plant, which need less budget, and when you make more money, expand your factory again. Doing Company are look forward to bringing fortune for you! welcome to contact us!

PREV:How to make oil from sunflower seeds at home?

PREV:How to make oil from sunflower seeds at home?

NEXT:Why does sunflower seeds need husking in sunflower oil making process?

NEXT:Why does sunflower seeds need husking in sunflower oil making process?

Leave a message

If you wanna to get more details about How to make sunflower oil in sunflower oil mill plant?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

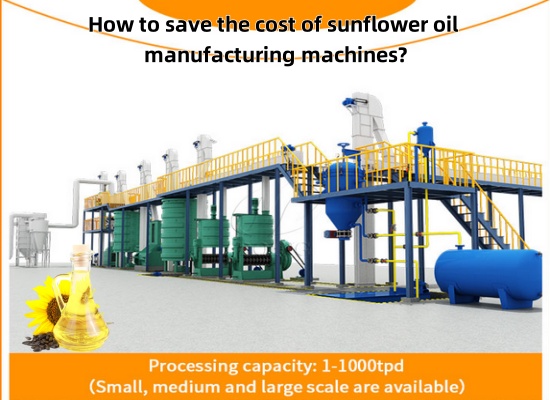

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?