How to invest in establishing a sunflower oil manufacturing factory?

Establishing a sunflower oil manufacturing factory can be a lucrative business, given the growing demand for vegetable oils worldwide. To ensure success, it's crucial to approach the establishment with proper planning, a clear strategy and investment. Here’s a step-by-step guide on how to invest in establishing a sunflower oil manufacturing factory:

Step Ⅰ. Conduct a Feasibility Study and Market Research

1. Market Demand: Study the demand for sunflower oil both locally and internationally. Research potential buyers, including wholesalers, retailers and industries like food processing, cosmetics and biodiesel production.

2. Competition: Analyze the competition in the region to determine how your sunflower oil manufacturing factory can stand out (price, quality or unique offerings).

Step Ⅱ. Plan the Sunflower Oil Manufacturing Factory Setup and Sunflower Oil Manufacturing Line

1. Location Analysis: Choose a location that is close to sunflower farms and has access to necessary infrastructure like transportation, power supply and labor.

2. Sunflower Oil Manufacturing Factory Design and Layout: Decide on the sunflower oil manufacturing factory size based on your target production capacity. Design the layout for optimal workflow, ensuring space for storage, sunflower oil manufacturing machinery, raw material intake, sunflower oil packaging and distribution.

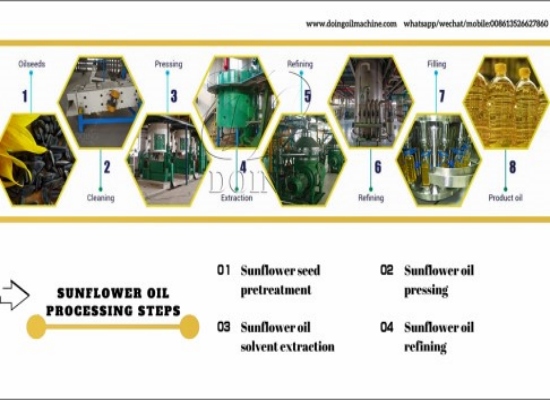

3. Sunflower Oil Manufacturing Line Investment: Purchase the necessary machinery for sunflower oil manufacturing, refining and packaging. Key equipment includes:

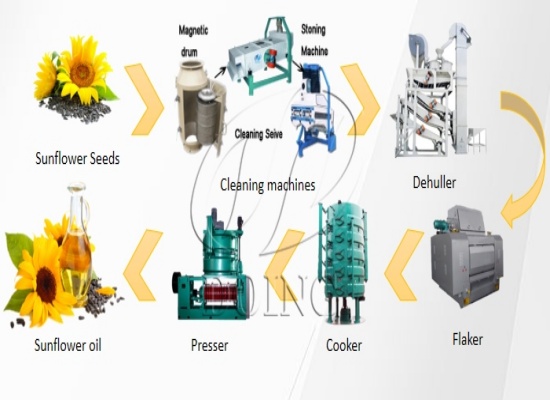

(1) Sunflower Seed Pretreatment Machine: It mainly includes sunflower seed cleaning machines (to remove impurities), sunflower seed shelling machine (to remove sunflower seed shells), sunflower seed kernel and shell separation machine (to separate sunflower seeds and shells) and roaster (to adjust temperature and moisture).

Sunflower seed pretreatment machine

Sunflower seed pretreatment machine

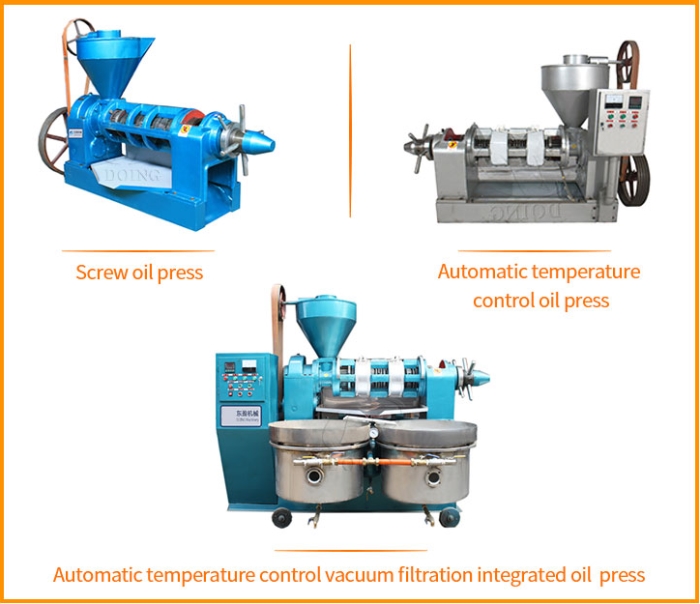

(2) Sunflower Oil Press Machine or Sunflower Oil Expeller: Taking Henan Glory Company as an example, we can provide you with three different sunflower oil press machines, namely screw oil press machine, automatic temperature control oil press machine and automatic temperature control combination oil press machine. They are all used for mechanical extraction of sunflower oil.

Three kinds of sunflower oil press machines

Three kinds of sunflower oil press machines

(3) Sunflower Oil Solvent Extraction Machine (optional, for higher oil yield): It mainly includes sunflower oil solvent extraction system, D.T.D.C system, evaporative stripping system and condenser & recovery system. The machines uses solvents like hexane to extract oil from the seed cake after pressing.

Sunflower oil solvent extraction machine

Sunflower oil solvent extraction machine

(4) Sunflower Oil Refining and Clarification Machines: They mainly include sunflower oil degumming machine, sunflower oil deacidification machine, sunflower oil decolorization machine, sunflower oil deodorization machine and plate filter. These machines are used to remove various impurities from sunflower oil, inhibit the increase in free fatty acid content and remove odors, ultimately making it suitable for consumption.

Sunflower oil refining machines

Sunflower oil refining machines

(5) Sunflower Oil Packaging Equipment: Bottling machines, labeling machines and capping machines for packaging finished oil in various quantities.

4. Automation: Depending on your budget, automation can improve efficiency and reduce labor costs. Automated systems for sunflower oil manufacturing, filtering and refining processes are commonly used in medium-to-large sunflower oil manufacturing factories.

Step Ⅲ. Financial Investment and Budgeting

1. Estimated Cost Breakdown:

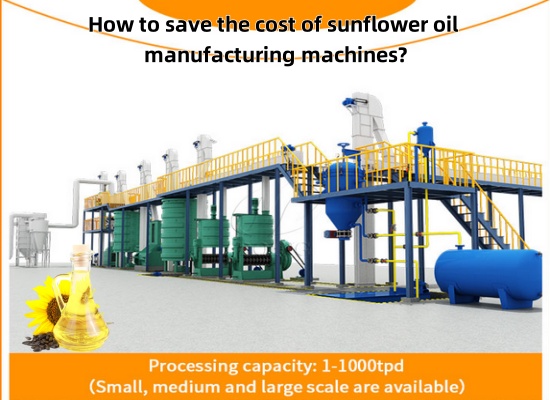

(1) Initial Investment: The capital required will vary depending on the size of the sunflower oil manufacturing factory and the type of sunflower oil manufacturing equipment you invest in. For a small and medium-scale sunflower oil manufacturing factory, the initial investment might range from $100,000 to $500,000, while larger-scale operations may require upwards of $1 million.

(2) Operating Costs: Raw materials, labor, utilities and distribution can range from $50,000 to $200,000 annually.

Raw materials-sunflower seeds

Raw materials-sunflower seeds

(3) Marketing and Branding: $10,000 to $50,000 for initial marketing and branding efforts. Also, budget for regulatory compliance.

2. Financing Options: You may need a combination of personal savings, loans, investors or venture capital to fund your sunflower oil manufacturing factory. Consider presenting your business plan to banks or investors for loans or equity funding.

Step Ⅳ. Set Up a Supply Chain and Distribution Network

1. Raw Material Supply: Sunflower seeds are the primary raw material. Determine the availability and cost of sunflower seeds in your area or from suppliers. Establish relationships with reliable seed suppliers.Such as establishing contracts with local farmers or suppliers for a continuous supply of high-quality sunflower seeds.

2. Logistics: Set up efficient logistics systems for the transportation of seeds to the sunflower oil manufacturing factory and the distribution of finished sunflower oil to markets.

3. Distribution Channels: Explore both local and international markets for your sunflower oil. You can sell through wholesale distributors, retailers, or directly to consumers via e-commerce platforms.

4. Branding and Marketing: Create a strong brand identity for your sunflower oil. Develop marketing strategies to reach your target customers, such as packaging, advertising and social media presence.

Step Ⅴ. Hiring and Training Staff

1. Staff Requirements: Hire staff for various roles in the factory, including machine operators, maintenance personnel, quality control experts, sales, and distribution teams.

2. Training: Ensure that employees are trained on proper operations, safety protocols, and quality control procedures. Consider offering regular training to improve efficiency and ensure quality production.

In conclusion, in the edible oil sector, where demand is growing, there is huge potential for investing in establishing a sunflower oil manufacturing factory. However, success demands meticulous planning across the entire value chain. By methodically addressing each critical phase outlined above and learning from existing industry challenges, you can establish a profitable and sustainable enterprise in this essential food sector. If you need any guidance or advice, please feel free to contact the Henan Glory Company and we will have professionals to analyze it for you.

PREV:Sunflower Oil Processing Equipment and Production Line Matching Plan

PREV:Sunflower Oil Processing Equipment and Production Line Matching Plan

NEXT:What are the advantages of sunflower oil refinery process?

NEXT:What are the advantages of sunflower oil refinery process?

Leave a message

If you wanna to get more details about How to invest in establishing a sunflower oil manufacturing factory?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?