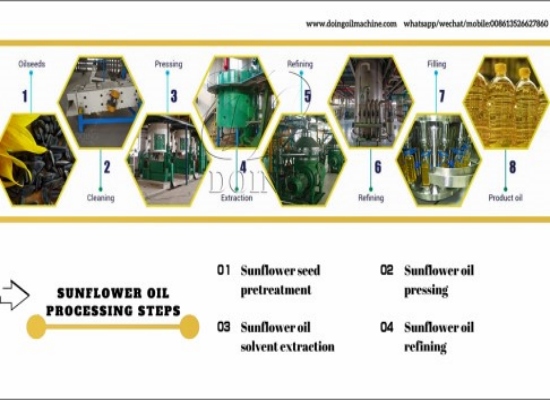

Sunflower Oil Processing Equipment and Production Line Matching Plan

As the demand for sunflower oil continues to rise both locally and globally, investing in a well-designed sunflower oil processing equipment and production line is a strategic move for entrepreneurs aiming to tap into this lucrative market. Below, Henan Glory will detail professional sunflower oil processing equipment and introduce production line matching plans for different scales to you.

I. Sunflower Oil Processing Equipment

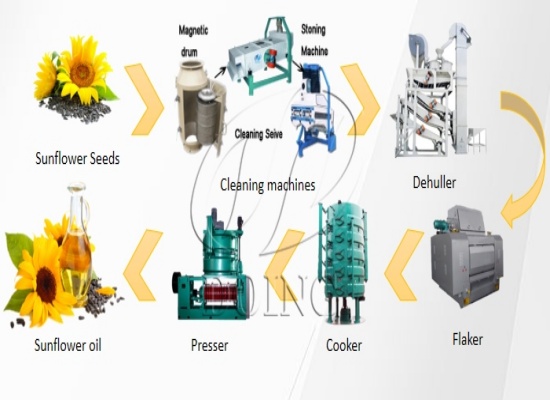

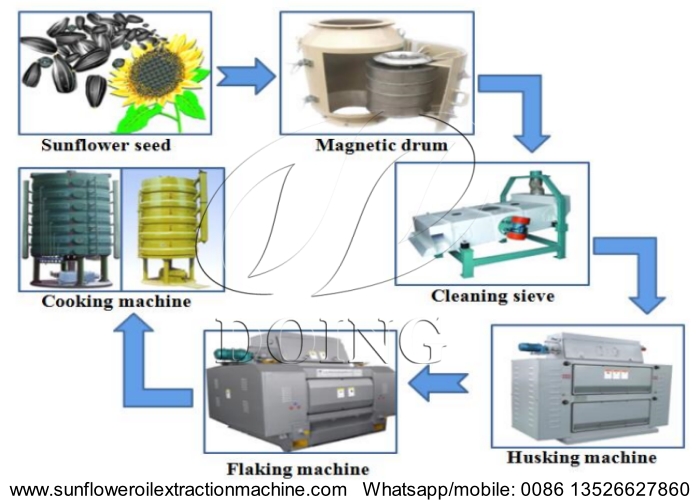

1. Pretreatment Equipment

Sunflower pretreatment equipment

Sunflower pretreatment equipment

Cleaning Equipment: Before processing, sunflower seeds must be thoroughly cleaned. Magnetic separator is employed to remove any metal impurities, while vibrating screen and destoner eliminate stones, dirt, and other materials. This step is crucial as impurities can damage the subsequent sunflower oil processing equipment and affect the quality of the finished oil product.

Shelling and Crushing Equipment: Sunflower seeds have a hard outer shell that needs to be removed. Specialized shelling machines are used to achieve this, and then the de-shelled seeds are crushed to increase the surface area for better sunflower oil extraction. Crushers are designed to break the seeds into smaller particles without over-damaging the kernel of sunflower seeds, optimizing maximum oil yield.

Flaking and Cooking Equipment: The flaking machine flattens the seeds into thin flakes, thereby further enhancing the efficiency of sunflower oil extraction process. Cooker helps to adjust the moisture and temperature of the seeds, making them more suitable for sunflower oil extraction.

2. Oil Extraction Equipment

Pressing Machines: There are three oil pressing machines, screw oil press, automatic temperature control integrated oil press machine and automatic temperature controlled oil press machine, can be used to extract sunflower oil. These pressers use mechanical force to squeeze the oil out of the sunflower seeds. The pressing process can be either cold-pressing or hot-pressing. Cold-pressing is preferred when the goal is to retain more of the natural nutrients and flavors of the sunflower oil, while hot-pressing generally results in a higher sunflower oil yield.

Sunflower oil pressing machines

Sunflower oil pressing machines

Solvent Extraction Equipment: In large-scale production, solvent extraction is often used to maximize oil yield. Solvent extraction equipment contains solvent extractor, D.T.D.C tower, evaporator, and evaporator condenser to extract the remaining oil from the pressed cake. This method can achieve a very low residual oil content in the cake, increasing the profitability of sunflower oil production line.

3. Oil Refining Equipment

Sunflower oil refining equipment

Sunflower oil refining equipment

Degumming Equipment: The first step in refining sunflower oil is degumming, which removes phospholipids and other gums from the crude sunflower oil. Degumming can be achieved through either water-degumming or acid-degumming methods, depending on the quality of the crude oil.

Deacidification Equipment: Deacidification is carried out to remove free fatty acids (FFA) from the sunflower oil. This is usually done by adding an alkaline substance (such as NaOH solution) to the oil, which reacts with FFA to form soapstock that can be separated from the oil.

Decolorization Equipment: Activated clay or other adsorbents are used in the decolorization process to remove pigments and other color-causing impurities from the sunflower oil. This step improves the color of the oil, making it more appealing to consumers.

Deodorization Equipment: Deodorization is the final step in the refining process, where the sunflower oil is heated under vacuum and steam is passed through it to remove any remaining volatile compounds, including odors and bad smells.

II. Production Line Matching Plans Based on Scale

1. Small-scale sunflower oil production line

If you simply want to produce crude sunflower oil, you only need to purchase a oil seeds roaster, a sunflower oil press machine, and a plate filter. You also can add cleaning equipment to the sunflower oil production line, such as vibrating screen, destoner, and magnetic separator, making a purer sunflower oil. The small-scale sunflower oil production line is suitable for capacity below 5tpd and is an ideal choice for homeuse.

2. Medium-scale sunflower oil production line

The medium-scle sunflower oil production line includes sunflower seed pretreatment equipment (cleaning machines, kernel shell separator, and roaster), sunflower oil pressing machine, filter and sunflower oil filling equipment. The sunflower oil production line can produce high quality sunflower oil and is suitable for capacity with 10-30tpd.

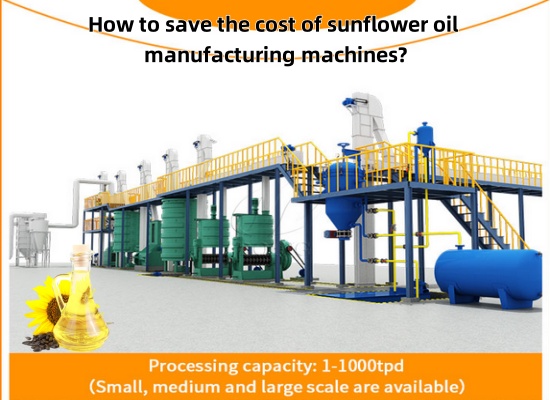

3. Large-scale sunflower oil production line

Large-scale sunflower oil production line

Large-scale sunflower oil production line

The large-scale sunflower oil production line contains sunflower seed pretreatment equipment (cleaning machines, cracker, cooker, flaking machine), sunflower oil pre-pressing equipment, filter, sunflower oil solvent extraction equipment, and sunflower oil refining equipment. The sunflower oil production line is suitable for capacity with 30-1000tpd, and offers high oil yield and efficiency.

If you would like to learn more, please contact Henan Glory and we can help you achieve your production goals!

PREV:Which sunflower oil press machine will profit you?

PREV:Which sunflower oil press machine will profit you?

NEXT:How to invest in establishing a sunflower oil manufacturing factory?

NEXT:How to invest in establishing a sunflower oil manufacturing factory?

Leave a message

If you wanna to get more details about Sunflower Oil Processing Equipment and Production Line Matching Plan, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?