What equipment is needed for the production of sunflower oil?

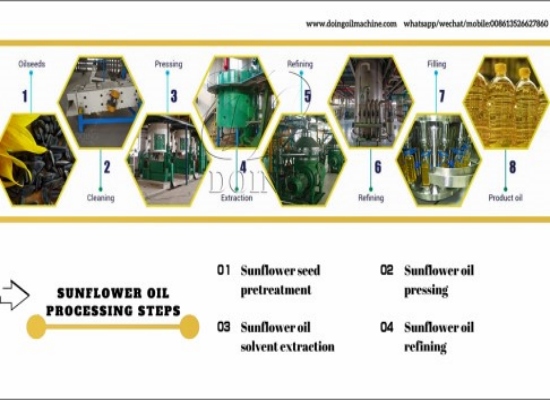

Three types of sunflower oil production equipment are commonly used: sunflower oil pressing equipment, sunflower oil solvent extraction equipment and sunflower oil refining equipment. What equipment is needed for the production of sunflower oil and the differences in the sunflower oil they produce? Let me briefly introduce you:

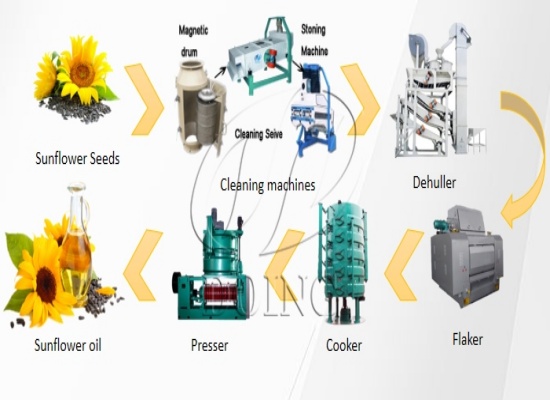

Sunflower oil press equipment

The sunflower oil press equipment uses the action of external mechanical forces to press the pre-treated sunflower seed, squeezing the fat out of it to obtain pressed sunflower oil. Sunflower oil obtained through the use of sunflower oil press equipment is free from additives and has an ideal nutrient content. However, the cake residue left after pressing contains a high amount of residual oil, which can result in fat loss if used in a single extraction.. Therefore, in the production of sunflower oil, oil refineries often use pre-press solvent extraction to increase the yield of sunflower oil, which requires the use of sunflower oil solvent extraction equipment.

Sunflower oil press equipment photo

Sunflower oil press equipment photo

Sunflower oil solvent extraction equipment

The sunflower oil solvent extraction equipment uses the solvent in full contact with the oil to produce oil, and the fat contained in the sunflower oil is leached to produce blended oil. The boiling point of solvent and fat is different, and the solvent is evaporated to obtain leached sunflower oil. The sunflower oil solvent extraction equipment can produce sunflower oil with high solvent extraction efficiency, but the crude oil leached by the sunflower oil solvent extraction equipment contains a small amount of solvent residue. The leached crude oil must be refined before it can be eaten. Refined sunflower oil can remove the solvent from the oil well and keep the oil safe. The leached meal is of good quality, can be used for livestock or animal feed and has a high product utilization rate.

Sunflower oil solvent extraction equipment photo

Sunflower oil solvent extraction equipment photo

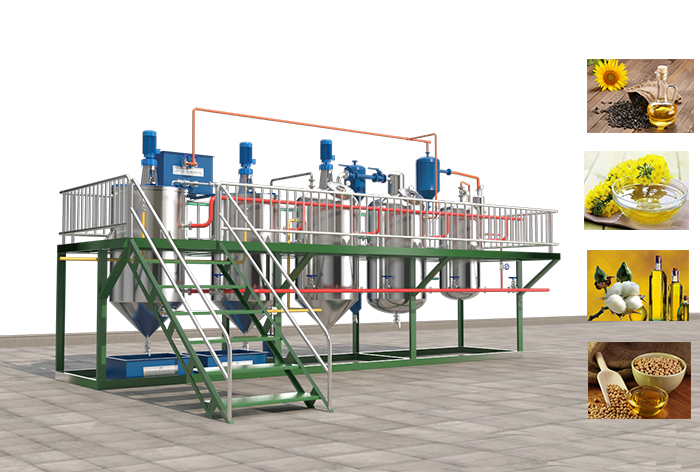

Sunflower oil refining equipment

Pressed oil and solvent extraction oil contain certain impurities. Some impurities are introduced during the manufacturing process, such as sediment, pomace powder, vegetable fibers and other impurities, while others are present in oils and fats such as phospholipids, free fatty acids, pigments, etc. Impurities that affect the quality of sunflower oil. Therefore, whether it is pressing or solvent extraction the oil, it must be purified with sunflower oil refining equipment to remove impurities from the oil. sunflower oil refining equipment purposefully removes impurities from sunflower oil through processes such as degumming, deoxidation, dehydration, decolorization and fat deodorization to ensure the quality and food safety of sunflower oil. Refined sunflower oil is more suitable for the taste of the general public, and can also extend the shelf life of sunflower oil. Refined sunflower oil can only enter the market for sale after passing inspection.

Sunflower oil refining equipment photo

Sunflower oil refining equipment photo

Generally, sunflower oil pressing equipment and sunflower oil solvent extraction equipment mainly extract oil from oil. This oil is called crude oil and needs to be processed. sunflower oil refining equipment is designed to clean the produced crude oil from impurities and harmful elements. Refined oil is the finished edible sunflower oil that we usually see in supermarkets. If you are interested in sunflower oil production equipment, please contact us.

PREV:How to extract oil from sunflower ? What equipment is needed?

PREV:How to extract oil from sunflower ? What equipment is needed?

NEXT:What are the types of sunflower oil press machines and their working principles

NEXT:What are the types of sunflower oil press machines and their working principles

Leave a message

If you wanna to get more details about What equipment is needed for the production of sunflower oil?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

Henan Glory's Sunflower Oil Extraction Machines were Successfully Shipped to Kenya

Henan Glory's Sunflower Oil Extraction Machines were Successfully Shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: Sunflower Oil Making Machines Sold to Customer in Kenya!

Good News: Sunflower Oil Making Machines Sold to Customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

Nigerian customer successfully purchased home use cooking oil extraction machine from Henan Glory Company

Nigerian customer successfully purchased home use cooking oil extraction machine from Henan Glory Company

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

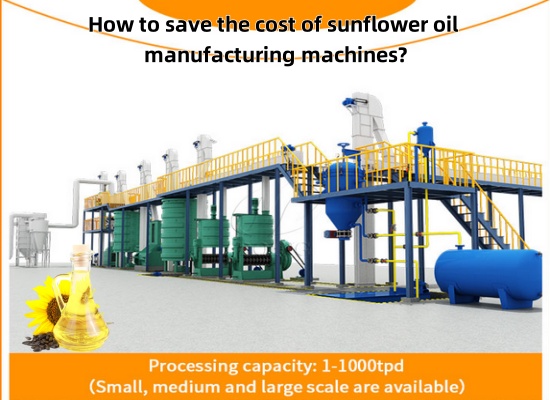

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?