What are the main components of sunflower oil refining equipment?

The main components of sunflower oil refining equipment include refining tanks, decolorization tanks, filters, vacuum systems and heat transfer systems, etc. According to different operating methods and processes, sunflower oil refining equipment can be divided into three types: batch sunflower oil refining equipment, semi-continuous sunflower oil refining equipment and fully continuous sunflower oil refining equipment. Each type of sunflower oil refining equipment has its own advantages, and you can choose the right equipment according to your actual needs.

Batch sunflower oil refining equipment

Batch sunflower oil refining equipment is a kind of equipment with simple and convenient operation and relatively low investment cost. It is suitable for frequent conversion of various oil products. The main components of sunflower oil refining equipment for batch include oil refining tank, decolorization tank, filter, vacuum system and heat transfer system. In the batch sunflower oil refining process, raw oil is first stored in refining tanks and impurities and fatty acids are removed through a degumming process. Next, acidic substances are removed through deacidification treatment. Finally, through the filter and adding bleaching earth and other decolorizing agents, the decolorizing effect is achieved, the pigment and impurities in the original oil are removed, and clear and transparent sunflower oil is obtained. The vacuum system provides the necessary vacuum environment for the decolorization and deodorization stages, and the heat transfer system provides the required heat for the crude oil in each process. In summary, batch sunflower oil refining equipment improves the quality and purity of raw oil through a series of processing steps.

Batch sunflower oil refining equipment photo

Batch sunflower oil refining equipment photo

Semi-continuous sunflower oil refining equipment

The main components of sunflower oil refining equipment for semi-continuous includes refining tanks, decolorization tanks, filters, deacidification and deodorization towers, fatty acid tanks, vacuum systems and heat transfer systems. Compared with batch sunflower oil refining equipment, semi-continuous sunflower oil refining equipment has moderate investment and lower oil loss, so it is widely selected. Semi-continuous equipment is added to the deacidification and deodorization tower and fatty acid tank to achieve continuous deacidification and deodorization processes.

Semi-continuous sunflower oil refining equipment photo

Semi-continuous sunflower oil refining equipment photo

Semi-continuous sunflower oil refining equipment combines the characteristics of batch and fully continuous sunflower oil refining equipment to improve production efficiency and product quality. In the process flow, the raw oil is first degummed in the refining tank, and then enters the decolorizing tank for oil decolorization, and the filter is used to filter fuller's earth for decolorization. The deacidification and deodorization tower realizes the continuous deacidification and deodorization process, while the fatty acid tank is used to collect the fatty acids generated during the deacidification stage. The vacuum system provides a vacuum environment for the decolorization and deodorization sections, and the heat transfer system provides heat for each section of crude oil.

Fully continuous sunflower oil refining equipment

Fully continuous sunflower oil refining equipment adopts continuous production at each stage, which has the advantages of small production consumption, low oil loss and more stable quality of refined oil. The main components of sunflower oil refining equipment for fully include refining tanks, centrifuges, decolorization towers, filters, deacidification and deodorization towers, fatty acid tanks, vacuum systems and heat transfer systems. Different from the first two types of equipment, the fully continuous sunflower oil refining equipment introduces a centrifuge to separate soap stock. The decolorizing tower is used to decolorize oil products, and the filter is used to filter fuller's earth for decolorization. The deacidification and deodorization tower realizes the continuous deacidification and deodorization process, while the fatty acid tank is used to collect the fatty acids generated during the deacidification stage. The functions of the vacuum system and heat transfer system are similar to the first two devices.

Fully continuous sunflower oil refining equipment photo

Fully continuous sunflower oil refining equipment photo

Whether it is batch, semi-continuous or fully continuous sunflower oil refining equipment, the goal is to improve the quality, stability and edibility of sunflower oils. These devices ensure that the sunflower oil meets the relevant quality standards and safety requirements during the production process through different technological processes and operation methods. The selection of suitable sunflower oil refining equipment depends on factors such as production scale, investment budget and product requirements. Henan Glory Oil has more than ten years of professional experience in the field of sunflower oil production equipment, providing customized services and after-sales support. For more information about sunflower oil refining equipment, please feel free to contact us.

PREV:What is the amount of sunflower seeds required to produce one liter of sunflower oil?

PREV:What is the amount of sunflower seeds required to produce one liter of sunflower oil?

NEXT:How much does a sunflower seed oil refining equipment cost?

NEXT:How much does a sunflower seed oil refining equipment cost?

Leave a message

If you wanna to get more details about What are the main components of sunflower oil refining equipment?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

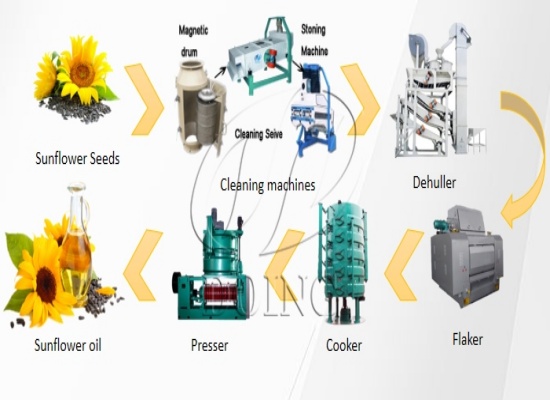

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

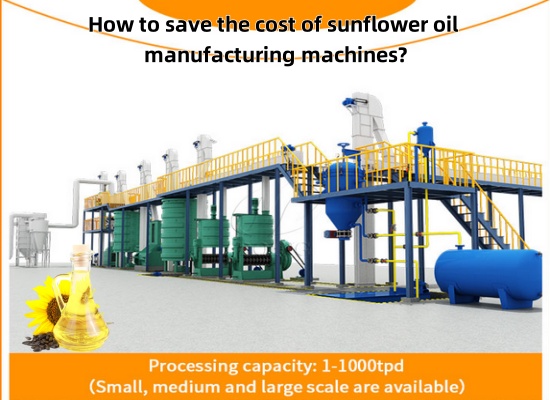

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?