What equipment is needed from sunflower seed cleaning to sunflower seed oil filling?

Global consumption of sunflower oil ranks fourth among all cooking oils, after palm oil, soybean oil and canola oil, and sunflower oil is one of the important cooking oils in European countries. Therefore, more and more people want to engage in sunflower oil production business, then you first need to understand the production process of sunflower oil and the equipment required.

Sunflower seeds photo

Sunflower seeds photo

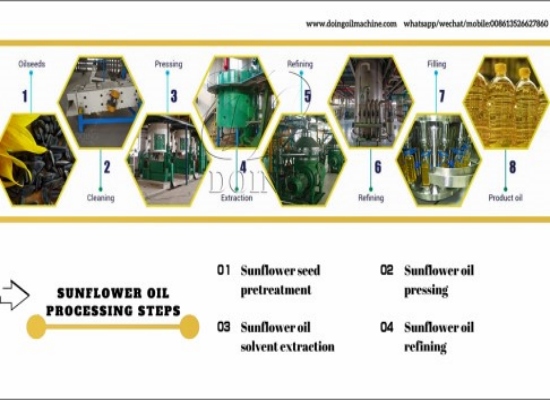

Generally speaking, the production process of sunflower oil is divided into three steps.

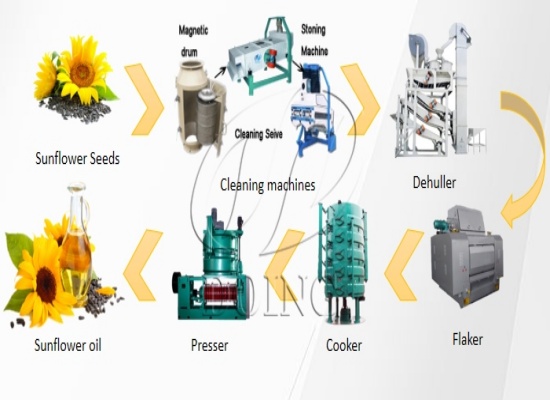

The first is oil extraction - pretreatment and pressing.

Sunflower seeds will have a lot of impurities in the process of collection and transportation, so generally speaking, sunflower seeds should be removed first. Impurities can affect the oil and damage the machine. It is then hulled to get clean sunflower kernels. Then it is crushed, steamed and fried before pressing to meet the requirements of temperature and moisture, and then pressed and filtered to obtain crude sunflower seed oil. The equipment required for this process is: vibrating screen - stone removal machine - magnetic separator - cracker - sunflower seed kernel and shell separator - flaking machine - cooker - oil press - filter.

Sunflower seed oil pretreatment and pressing machine

Sunflower seed oil pretreatment and pressing machine

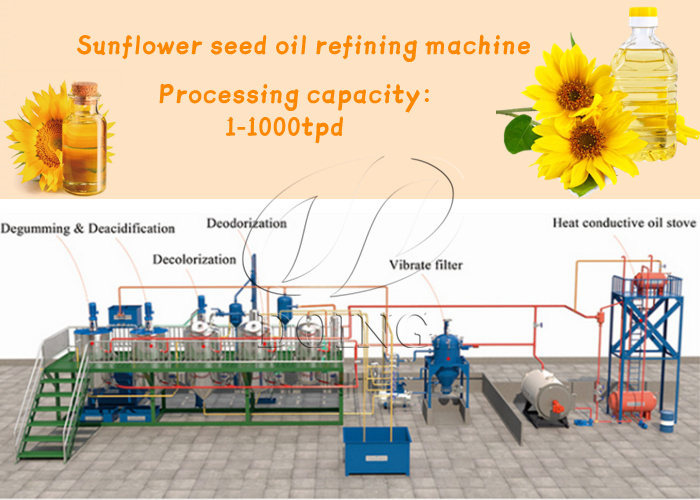

The second is refining.

Removing harmful substances such as phosphoric acid from crude oil. Sunflower oil is degummed, deacidified, decolorized and deodorized during the refining process. The clear and odorless refined oil can be obtained, which can meet the edible oil standard required by the state. The required equipment is:(Recommend reading:1-20TPD batch type sunflower oil refinery plant)

Sunflower seed oil refining machine

Sunflower seed oil refining machine

►Refining line including: acid refining, alkali refining, water washing and neutralization pot, degreasing and decolorizing pot;

►Oil furnace/electric heating system: to provide the heat energy required for production;

►Vacuum pump: to provide the vacuum required for decolorization and deodorization Environment;

►Leaf filter/filter press: filter clay in decolorized oil;

►Air pressure machine: blow dry decolorized clay;

►Steam generator: generate steam required for deodorization and distillation.

Lastly is dewaxing.

Removing excess wax from the oil, which tastes better. Methods of cryogenic prospecting followed by mechanical separation of precipitated waxes. The resulting oil can be sold at a better price and is more popular. The equipment required are: crystallizing tank, refrigeration unit, air compressor and other equipment.

The refined oil after dewaxing can be packaged and sold. Packaging equipment generally includes filling machines, capping machines, labeling machines, inkjet printers, packing machines and other equipment. Customers need to determine the capacity of the bottle first, and then they can choose the appropriate packaging equipment.

Sunflower seed oil packaging equipment

Sunflower seed oil packaging equipment

The above is all the equipment required from sunflower seed cleaning to sunflower seed oil filling. You can choose according to your actual needs, or you can contact Henan Glory Company, we can design sunflower seed oil production plan for you free of charge, and provide a complete set of sunflower seed oil production equipment.

Leave a message

If you wanna to get more details about What equipment is needed from sunflower seed cleaning to sunflower seed oil filling?, you can send E-mail to sales@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Multifunctional fully automatic commercial use sunflower oil expeller

Multifunctional fully automatic commercial use sunflower oil expeller

-

D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

-

Single screw sunflower seed oil expeller machine

Single screw sunflower seed oil expeller machine

-

Solvent extractor for sunflower oil extraction plant

Solvent extractor for sunflower oil extraction plant

-

Sunflower oil filling machine

Sunflower oil filling machine

-

Sunflower oil production line

Sunflower oil production line

-

Small scale sunflower seed oil processing plant

Small scale sunflower seed oil processing plant

-

Sunflower seeds preparation & oil pressing line

Sunflower seeds preparation & oil pressing line

-

Small scale sunflower seeds oil pressing plant

Small scale sunflower seeds oil pressing plant

-

30-1000TPD full-continuous sunflower oil refinery plant

30-1000TPD full-continuous sunflower oil refinery plant

-

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

DOING Company stocks multi-functional sunflower oil press machines in its overseas warehouse in Nigeria

-

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

Henan Glory's sunflower oil extraction machines were successfully shipped to Kenya

-

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

Ghana customer purchased YZYX10-8 cooking oil expeller from Henan Glory Company

-

Good News: sunflower oil making machines sold to customer in Kenya!

Good News: sunflower oil making machines sold to customer in Kenya!

-

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

Henan Glory Oils & Fats Engineering CO., LTD will participate in the 2023 Russia Moscow Feed and Grain Processing Exhibition MVC Expo on June 21st.

-

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

YZYX70WX sunflower oil extraction machine was purchased by a customer from Kenya

-

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

Malawi customer purchased YZYX70 cooking oil press from Henan Glory Company

-

Sunflower oil processing machine promotions!

Sunflower oil processing machine promotions!

-

How to buy sunflower oil making machines in Kenya?

How to buy sunflower oil making machines in Kenya?

-

What tools are used in sunflower oil refinery process?

What tools are used in sunflower oil refinery process?

-

What is the extraction process of cold pressed sunflower oil?

What is the extraction process of cold pressed sunflower oil?

-

How to ensure the normal operation of the sunflower oil milling machines?

How to ensure the normal operation of the sunflower oil milling machines?

-

How to save the cost of sunflower oil mill machinery?

How to save the cost of sunflower oil mill machinery?

-

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

What is the amount of sunflower seeds required to produce 1 ton sunflower seed oil?

-

Is it worth investing in an sunflower seeds oil mill plant?

Is it worth investing in an sunflower seeds oil mill plant?

-

How much does it cost to set up a sunflower oil processing plant in Zambia?

How much does it cost to set up a sunflower oil processing plant in Zambia?